Finite Capacity Scheduling

A New, Simpler Finite Scheduling Algorithm - In 14 Minutes You Can Understand How It Works and Download A Working Example in Excel By Gabriele Tettamanzi / November 5, 2023 Finite scheduling calculates the begin and end of each job to be done in production.

青蛙SAP分享 Froggy's SAP sharing Capacity Leveling with Finite Capacity Forward Scheduling for

http://www.scheduler123.com Excel-based Production Scheduling System part C-3: "One Button" Finite Capacity Scheduling. Forward Scheduling sequenced by Prior.

MxAPS Advanced Finite Capacity Scheduling Comprehensive Overview YouTube

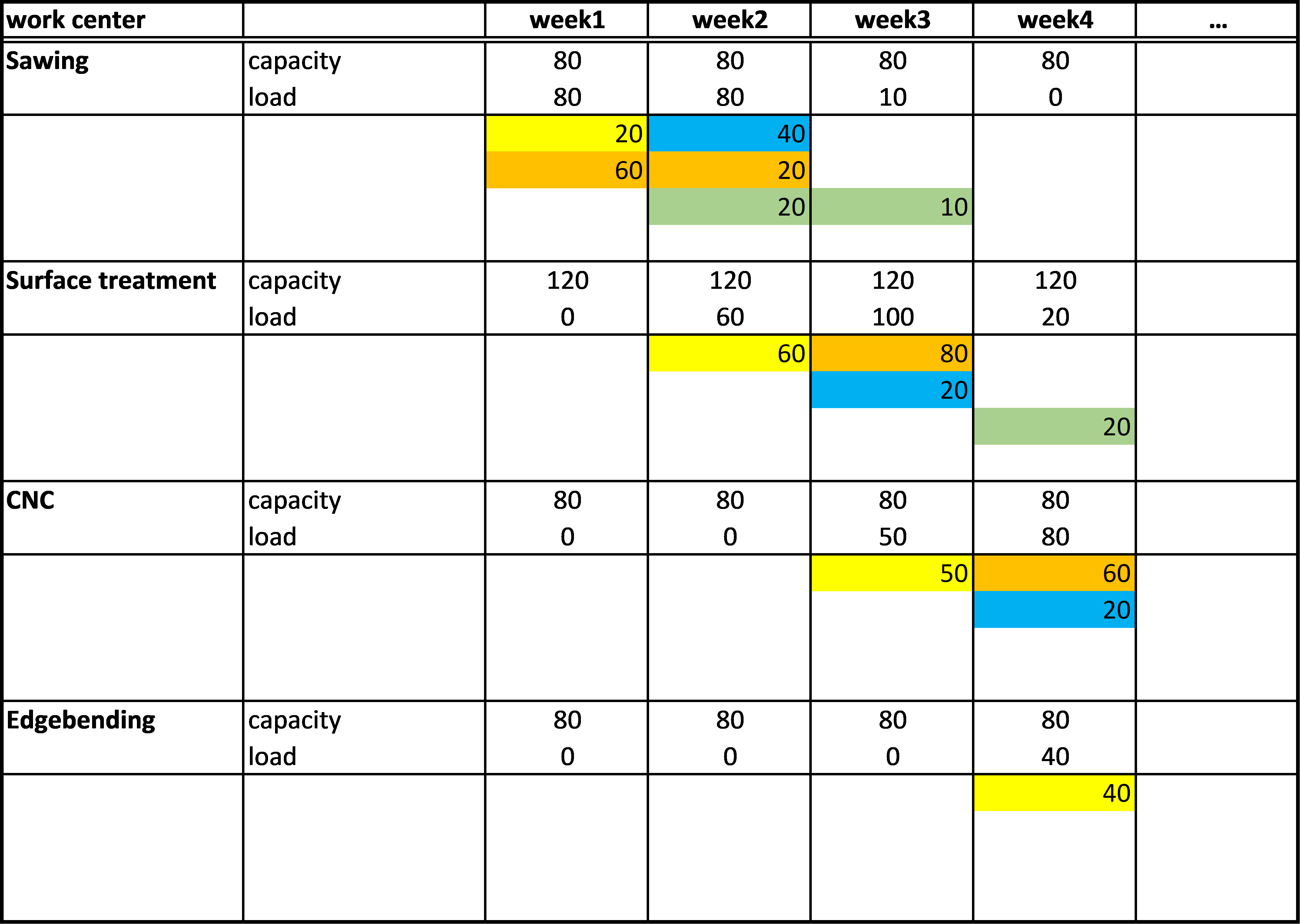

The finite scheduling calculates the exact begin and end of each job considering routing and quantity for the workload and work center availability by a calendar for the capacity.

Why job shop scheduling starts with defining resource capacity [video]

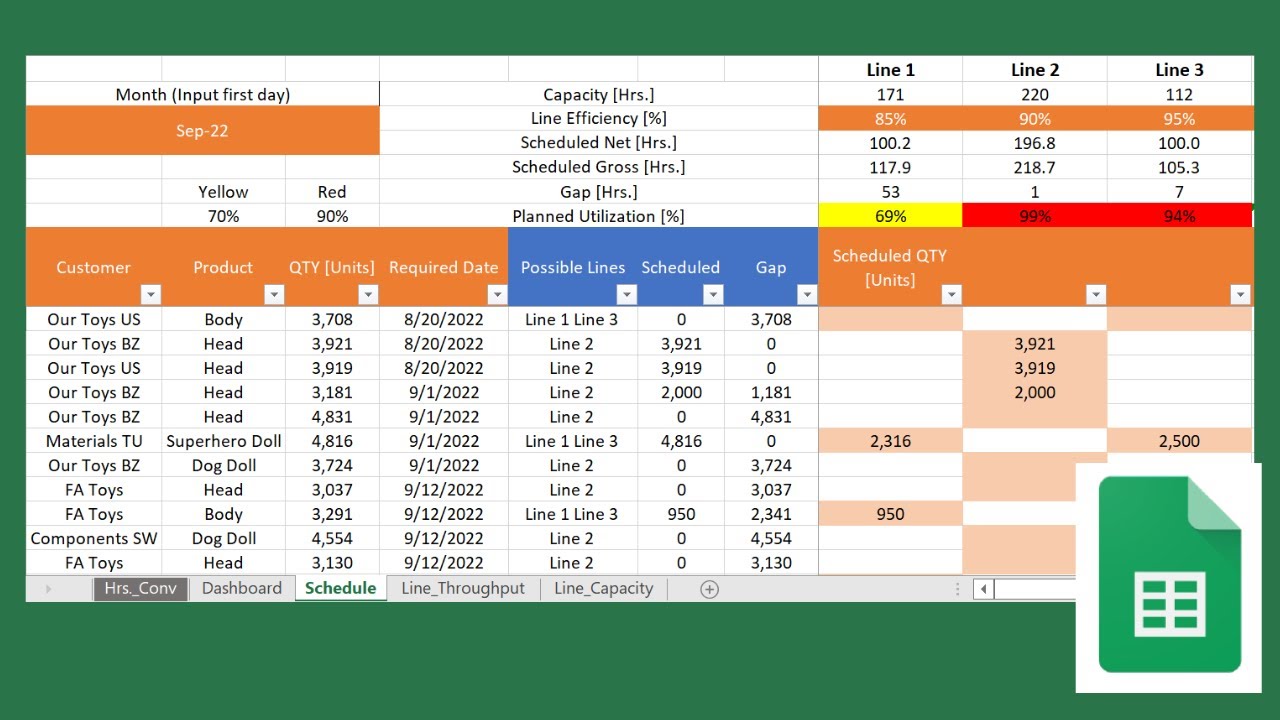

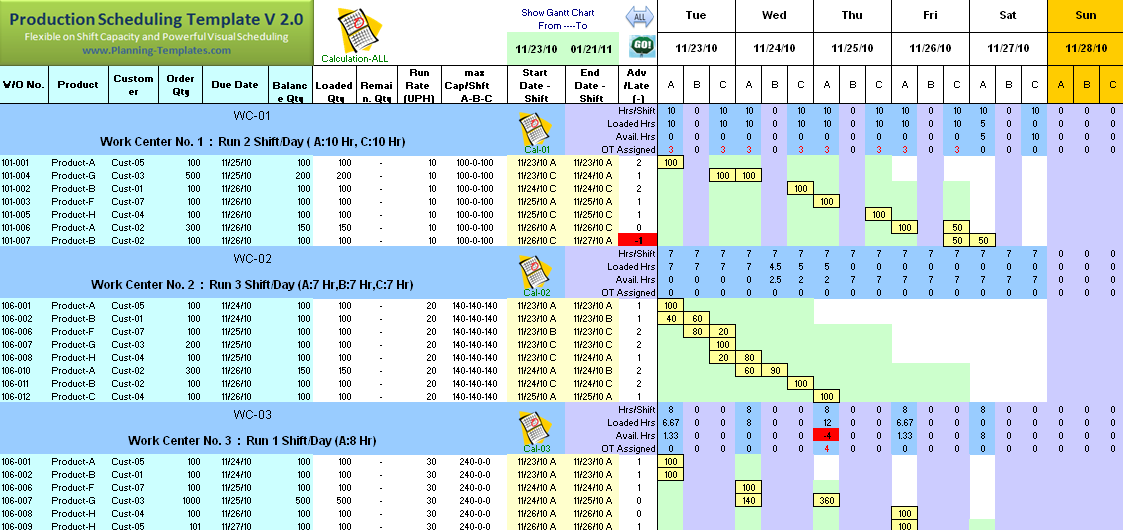

Finite Capacity Loading - Production Planning & Scheduling in Excel Advanced Production Scheduling Template Create Daily Production Schedule with Confidence! Ensure that you can build product On Time, Without Capacity Issues!

Our take on finite capacity scheduling with Business Central

Finite Capacity Scheduling (FCS) is a production planning and scheduling approach used by enterprise manufacturers to optimize their resources and operations within the constraints of their finite capacity. It helps manufacturers balance supply and demand while considering factors such as available resources, labor, machines, and time.

The Difference Between Finite Capacity Scheduling and Infinite Capacity Loading

With finite capacity scheduling, operations are only scheduled when resources and materials are available. This technique can help you optimize your inventory flow, shorten the delivery time, and accurately plan production to meet changing demand. Finite Capacity Planning Made Easy

Finite Capacity Planning & Scheduling

Drive Manufacturing Excellence with Advanced Finite Capacity Scheduling in Business Central. MxAPS revolutionizes production planning and scheduling, transforming it from an inaccurate and time-consuming task into a responsive, repeatable, and highly accurate decision support activity. Seamlessly integrating with Dynamics 365 Business Central.

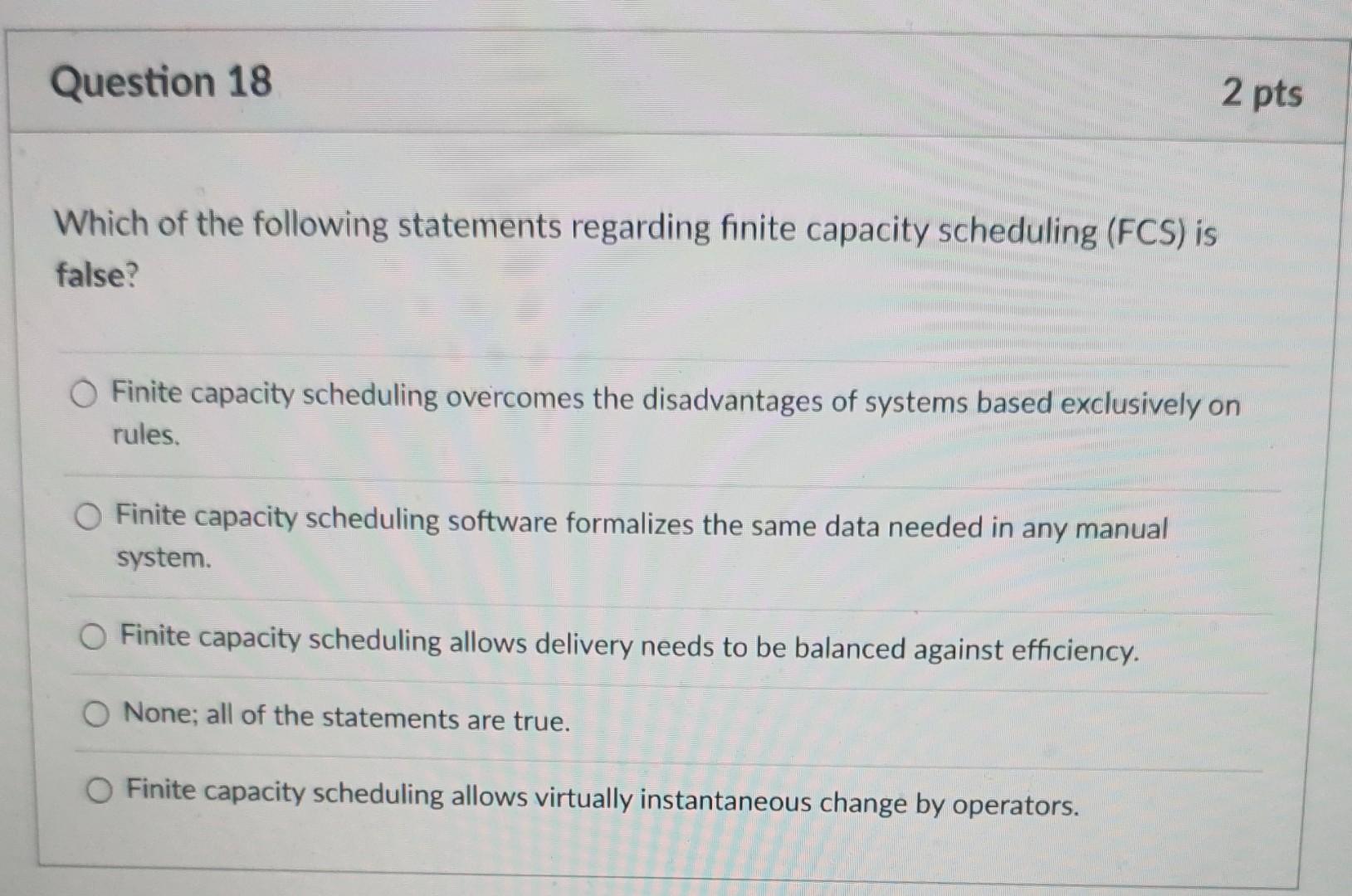

Solved Question 18 Which of the following statements

A fully automated material planning, capacity planning and finite scheduling tool built with ZERO coding in Excel.

Finite Capacity Scheduling Process Diagram Sample Ppt Files Presentation PowerPoint Templates

Finite production scheduling on excel. Hi everyone, new job with no scheduler or mrp/erp system in place. Series production of small electrical devices. Is there any chance of creating on VBA a scheduler which output is delivery date, and input Is finite capacity per line, man hours per product as costraints?

production scheduling finite excel YouTube

Finite Loader's Main Features Production Planner or Scheduler can load Job Order in Shift Schedule to meet Customer Order Due Date. Provide visual control tool to alert them when out of Due Date or Over Capacity! 1. Shift Schedule : Flexible Number of Shift per Day You can mix the different number of shifts per day in the same production schedule.

Finite Scheduling SFJ Systems

ABSTRACT. This chapter discusses the Many companies use Excel for production scheduling. Some believe that it is effective, while some realize that it's cumbersome and ineffective but don't know where to turn. Compared to specialized software, Excel is inefficient for both the scheduler's time and the company's production resources.

Master Production Schedule Template Excel printable schedule template

Finite capacity scheduling is so-called because it takes capacity into account from the very outset. The schedule is based on the capacity available. Infinite capacity scheduling - the approach used in MRP II - schedules using the customers' order due date and then tries to reconcile the result with the capacity available.

Finite Capacity Planning Top Priority Systems

The objective is to automate finite capacity scheduling via algorithms, but also to make these algorithms understandable and clear to users — trust is key for daily adoption! One of the key elements is to feed the scheduling engine with consistent priorities, whether the requirements are replenishing inventory (MTS) or sales orders (MTO).

62.02 Finite Scheduling YouTube

The purpose of finite capacity scheduling is to ensure that work proceeds at an even and efficient pace throughout the plant. Finite capacity planning and scheduling creates a more realistic schedule for the production processes than the infinite loading approach creates.

Finite Capacity Scheduling Optimise and balance schedule changes

How rough-cut capacity planning and finite scheduling work together. The core content is covered in the first 60 minutes. Then Q&A for another 20-30 minutes. You will get a download link immediately after the event with the Template and the finished Capacity Planning Tool. ← Previous Post Next Post →

Finite Capacity Scheduling

In manufacturing operations, finite capacity scheduling is an method to understanding how much work can be produced in a certain time period, and assigning resources to tasks in an optimum order considering all limitations.